Method Of Install Grinder Machine

.jpg)

Grinder machine installation, use, maintenance and repair

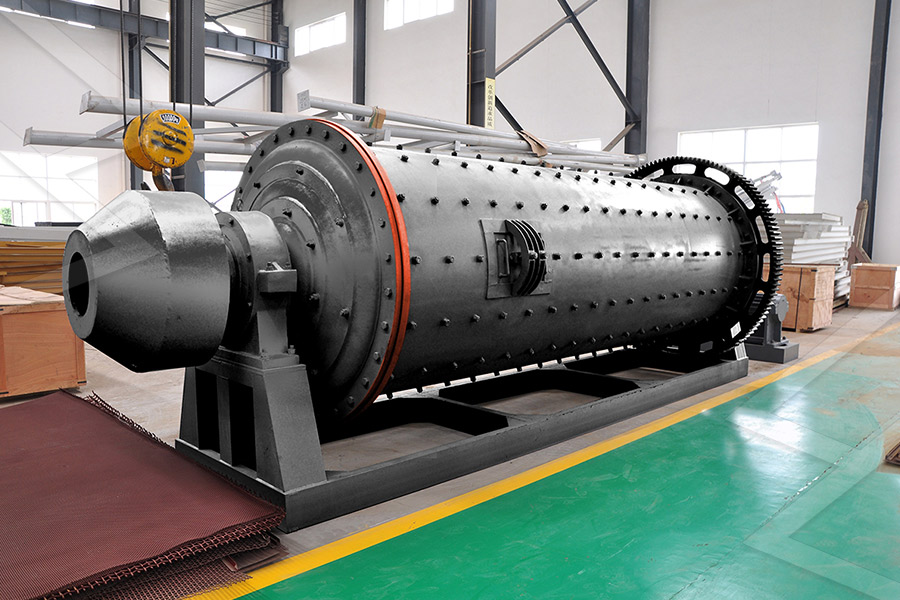

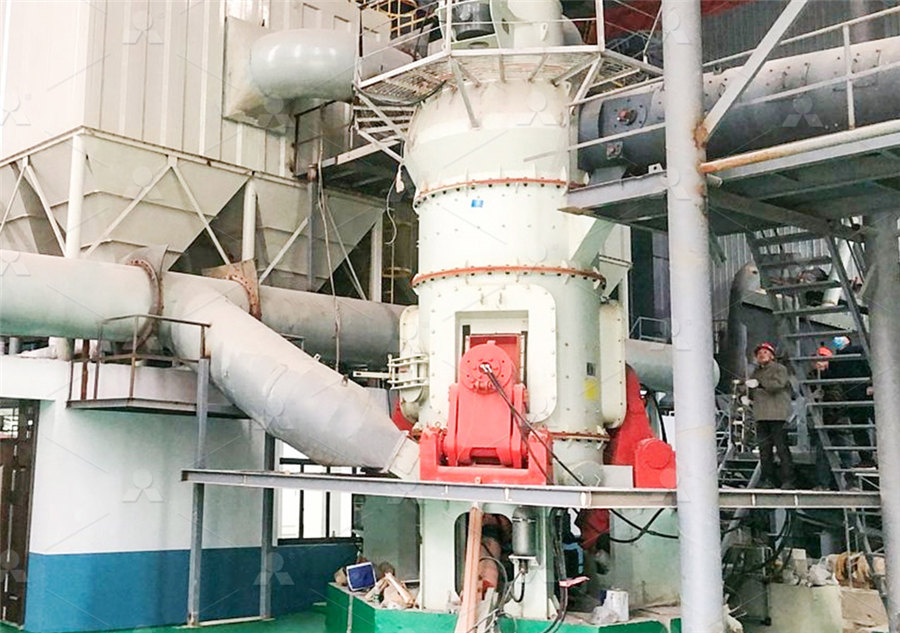

2021年8月20日 First, the installation of Grinder machine The quality of grinder machine installation quality, the ability of machine is the key to normal work Various types of grinder machine installation method and sequence of roughly the same3 天之前 INTRODUCTION This is a guide to handheld grinding The information is mainly of a practical nature, intended for operators and others professionally involved with these tools Pocket Guide to Grinding Technique Atlas CopcoSurface Grinding Machine: Types, Parts Working Process : A surface grinder consists of an abrasive wheel, a chuck (a workplace holding device) and a rotary table The surface grinder is generally used for finishing the workpiece or the Surface Grinding Machine: Types, Parts The challenges associated with highspeed grinding include improved machine capability, improved technology to cope with high grinding wheel speeds, optimized process conditions, Principles of Modern Grinding Technology ScienceDirect

(PDF) Principles of Modern Grinding Technology

2013年1月1日 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, highspeed grinding 2018年7月11日 TC 9524 Chapter 5 GRINDING MACHINES Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel GRINDING MACHINES Carnegie Mellon University2021年5月27日 Various types of grinder mill installation method and sequence of roughly the same To ensure the smooth functioning of grinder mill and reducing the harm to the buildings, Grinder mill installation, use, maintenance and repair2021年4月16日 Grinding machines or tools use an abrasive wheel to remove metal from the workpiece When the wheel rotates, it cuts material off the workpiece by cutting The amount of material removal is dependent on factors Intro to Grinding Methods, Machines and Tools

Chapter 17: Grinding Methods and Machines

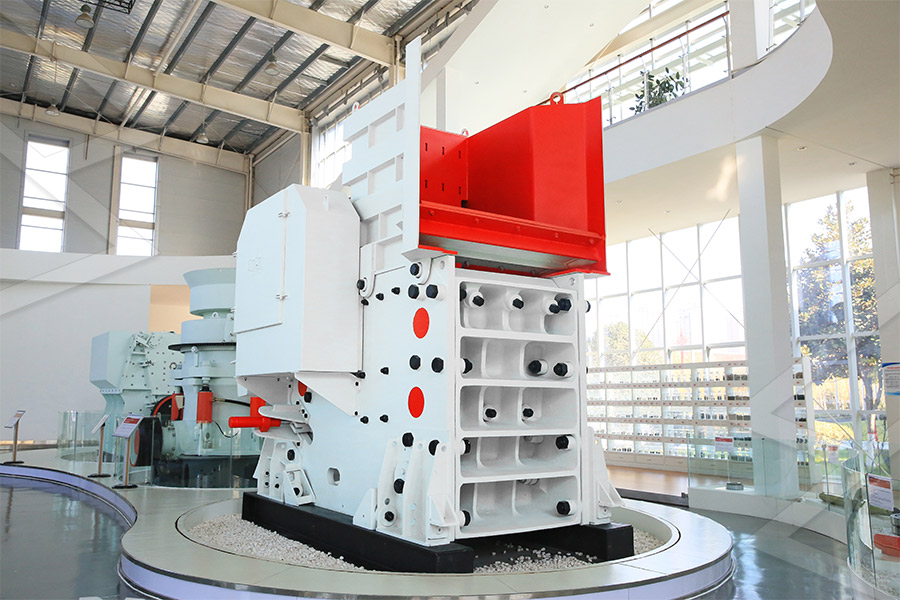

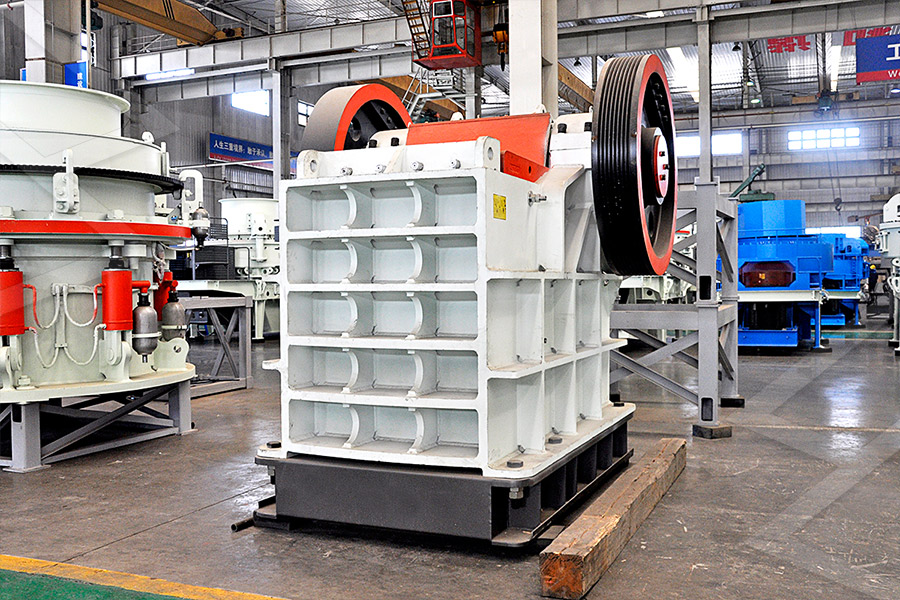

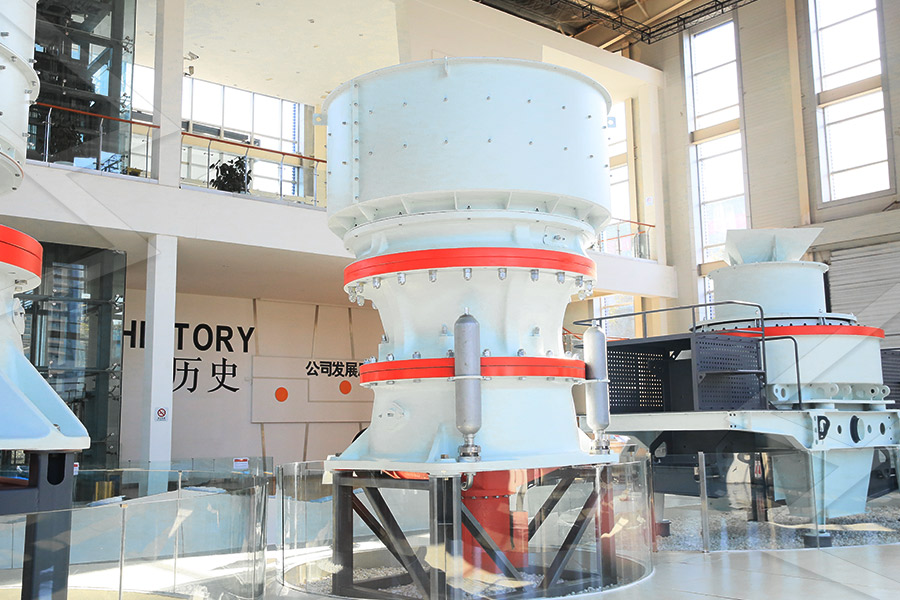

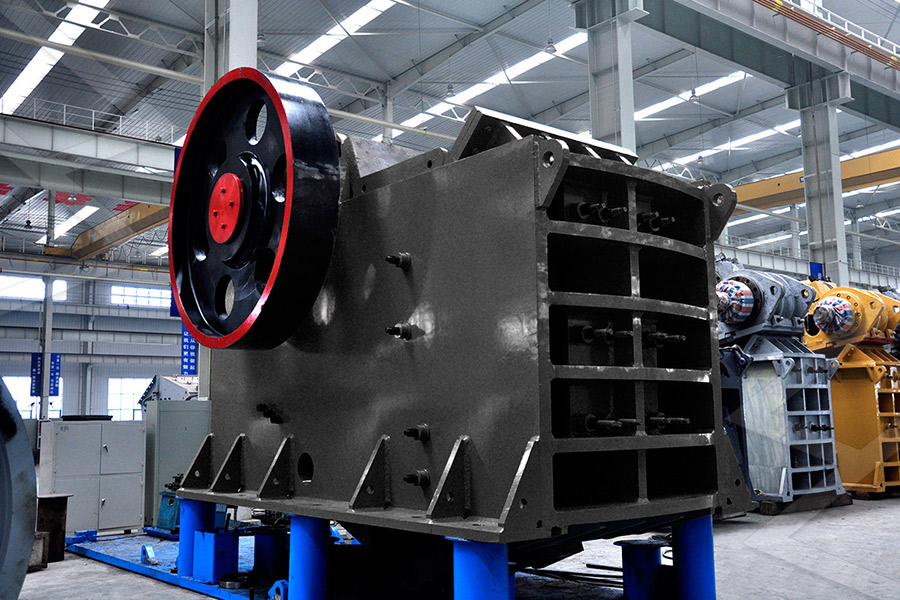

2020年6月29日 Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, 2023年12月25日 To achieve a fundamental reduction in the carbon emissions associated with grinding machines, it is imperative to systematically explore lowcarbon considerations in the design phase The spindle is a significant LowCarbon Optimization Design of Grinding These machines do their work in distinctly different ways Compression is the characteristic action of crushers Grinders employ impact and attrition, sometimes combined with compression; ultrafine grinders operate principally by attrition Grinding: Grinding Methods – Technology of 2021年5月5日 A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it Grinding Machine: Definition, Parts, Working

Intro to Grinding Methods, Machines and Tools

2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, 2021年10月14日 Maintenance method of large machine tool ball screw wear based on brush plating technology and precision grinding technology October 2021 DOI: 101117/12Maintenance method of large machine tool ball screw wear 2019年9月27日 A scientific and technical literature review on machines designed to grind fodder grain revealed that the existing designs of grinding machines—those based on destruction by impact, cutting, or (PDF) Studies of a Rotary–Centrifugal Grain Grinder Using a 2024年4月19日 Discover the inner workings of grinding machines and learn how they transform raw materials into finished products 899 Sheridan Dr, West Chester, Pennsylvania Mon – Sat: 9:00am–18:00pm Sunday CLOSED Grinding Method: Grinding Wheel Material: Grinding Wheel Size: Grinding Speed: Grinding Pressure: Grinding Accuracy: Grinding Capacity The Grind: Understanding The Processes Of Grinding Machines

The Powerful Advantages Of A Cnc Grinder Machine For

2024年4月18日 Safety: Safety is a top priority in any industry, and CNC grinder machines offer several safety advantages over manual grinding methods These machines are equipped with advanced safety features, including interlocks and protective enclosures, which prevent access to hazardous areas during operation Additionally, CNC grinder machines minimize Here’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas 1 Surface Grinders: A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table 2 Cylindrical Grinders: A cylindrical grinder is used for shaping the outside of a workpiece 3What Is Grinding Machine? Definition, and Types Mechdaily2024年10月10日 A cylindrical grinder operator must be familiar with the machine itself, as well as how to select and utilize wheels, workholding, and coolant, in order for the grinding operation to be successful This foundational knowledge is necessary to reduce scrap, increase quality and production rates, and lower costsBasics of the Cylindrical Grinder Purdue University2022年11月14日 Creating textures on abrasive wheels is a strategy that allows a significant improvement in grinding operations The reduction of the internal stresses in the workpiece and the temperature during the grinding operation Texturing Methods of Abrasive Grinding Wheels:

.jpg)

How to Use a Bench Grinder: 9 Steps (with Pictures) wikiHow

2021年3月22日 Make sure the grinder is tightly secured to the bench Check that the tool rest is in place on the grinder The tool rest is where the metal item will rest as you grind it The rest should be secured in place so there is a 1/8 inch (3 mm) space between it and the grinding wheel Clear the area around the grinder of objects and debris2023年8月2日 Jig grinding is a specialized type used to grind complex shapes and holes with the highest precision This method involves using a jig grinder, a machine tool for grinding complex shapes and holes in metal and ceramics The Details of Accurate Grinding: A Practical 2020年8月28日 This paper synthesizes the design of an infeed cylindrical grinding system into a total system composed of the grinding mechanism and the grinding machine characteristics The causalities between the grinding parameters and the machine structures are discussed, and the infeed grinding processes are analyzed as outputs that represent responses to the inputs The Design of an Infeed Cylindrical Grinding Cycle MDPI2023年3月9日 Disadvantages of Grinding Machine Particularly if they are automated or computerized, grinding machines can be pricey In some environments, the noise that grinding machines can make can be an issue Grinding machines can generate a lot of dust and debris If it is not properly controlled, it can harm the operator’s healthGrinding Machine: Parts, Working, Operations, More [PDF]

PHILIPPINE NATIONAL University of the Philippines Los

2020年6月8日 Agricultural machinery Coffee grinder Methods of test 1 Scope This standard specifies the methods of test for coffee grinders Specifically, it shall be used to: 11 verify the mechanisms, dimensions, materials and accessories of the coffee grinder and the list of specifications submitted by the manufacturer;2024年3月11日 Bench Grinder SAFE WORK METHOD STATEMENT (SWMS) TASK OR ACTIVITY: Bench Grinder Adequate signage and labelling: Install clear, visible warning signs and labels on or near the bench grinder, outlining proper usage guidelines and cautionary measures Isolating damaged machines: If a bench grinder is found to have any issues duringBench Grinder Safe Work Method Statement (SWMS)2024年10月17日 These machines are used to produce various external cylindrical surfaces, including straight, tapered, stepped, or profiled shapes delves into the different types of cylindrical grinding machines: Plain Centre Type Cylindrical Grinder: This machine, illustrated in Figure 298, operates with workpieces held between headstock and tailstock centersNavigating Cylindrical Grinding Machines: A Comprehensive 2023年5月18日 9 Surface Grinder Machine Cleanliness and Maintainance Keep the surface grinding machine clean and free from debris Regularly remove swarf, chips, and grinding residue from the work area and coolant tanks Clean and lubricate machine components as per the manufacturer’s recommendations to ensure optimal performance and longevitySurface Grinding Tips 10 Essential Tips Kaast Machine Tools

How To Put A Disc On An Angle Grinder TheHandyBee

Angle grinders are versatile tools that can be used for a variety of tasks, from cutting and grinding to polishing and sanding When preparing to install a disc on your angle grinder, it’s important to prioritize safety ANSI B77 Safety Requirements for Abrading Materials with Coated Abrasive Systems requires that machines designed 2023年5月18日 Cylindrical grinding machines are often used for manufacturing parts with tight tolerances and cylindrical shapes, such as shafts, rods, and bearings 3) Centerless Grinding Machine: In this type of grinding machine, the workpiece is supported between two wheels, one grinding wheel, and one regulating wheelDifferent Types of Grinding Machines and How to Use a Grinder 13 Amp Coffee Machine Installation Guide PDF 16 Amp 16 Amp Coffee Machine Installation Guide PDF: 20 Amp 20+ Amp Coffee Machine Installation Guide PDF Water Supply Water supply terminating in a standard washing Coffee Machine Install Guide Arden Coffee 2024年4月19日 Learn about the different types of grinder machines to find the perfect one for your specific needs 899 Sheridan Dr, West Chester, Pennsylvania Mon – Sat: 9:00am–18:00pm Sunday CLOSED +1 610497 Understanding The Various Types Of Grinder

Grinder Machine – Working, Types, Applications, Pros Cons

2023年5月5日 A grinding machine consists of the following parts: 1 Base – The base of the grinding machine supports the other parts of the machine It is made of cast iron and rests on a flat foundation 2 Column – The column is a vertical structure that supports the grinding wheel and the grinding head It is made of cast iron and has a dovetail slide on which the grinding 2023年4月13日 The grinding part of the machine is timeconsuming and takes less energy than the dry milling process Due to this, it is costeffective for the users To prevent any mistakes, you can make the process effective by analyzing the material sample before grinding the actual item The method of drying consumes time as well as is a costly How to Use a Wet Grinder? Expert Techniques For Beginners2023年6月20日 Accuracy design is an important and essential step for CNC machine tools, and traditional methods always focus on the accuracy optimization itself and ignore other objectives, such as lowcarbon manufacturing In this paper, a novel slider grinding machine is designed as an illustrative example to build the accuracy design model This paper Accuracy design optimization of a CNC grinding machine 2017年7月28日 With Grinders Machine Safety PeerReviewed “A worker’s first day shouldn’t be his A ring test is one method of checking whether a wheel is cracked or damaged OSHA (1996) concisely describes this test in Sec Install a Safety Gauge Near the Grinder A common grinderrelated safety violation is related to clearances OSHA (1996 PeerReviewed Working Safely With Grinders American

.jpg)

The Importance Of Rpm In Grinder Machine Performance

2024年4月19日 Learn why RPM is a critical factor in determining the performance of a grinder machine and how it impacts efficiency and quality 899 Sheridan Dr, West Chester, Pennsylvania Mon – Sat: 9:00am–18:00pm while a tight belt can increase the RPM Consult the manufacturer's manual to identify the appropriate method for adjusting the belt 2022年10月4日 Grinding is a machining method that removes small amounts of material from both flat surfaces and cylindrical shapes Surface grinders reciprocate the work on a table while feeding it into the grinding wheel and superfinishing Double disc grinding is another machine process that lets parts pass one or more times between two counter 9 Types of Machining Processes Xometry2024年1月23日 Initial Investment: Grinding machines, especially those used for precision applications, are costly Highend machines with advanced features like CNC systems are even more expensive Basic Grinding Machines: Entrylevel grinding machines, suitable for smallscale operations or less complex tasks, typically range from $5,000 to $20,000What is Grinding: Definition, Process, Types Specifications2023年12月25日 To achieve a fundamental reduction in the carbon emissions associated with grinding machines, it is imperative to systematically explore lowcarbon considerations in the design phase The spindle is a significant LowCarbon Optimization Design of Grinding

.jpg)

Grinding: Grinding Methods – Technology of

These machines do their work in distinctly different ways Compression is the characteristic action of crushers Grinders employ impact and attrition, sometimes combined with compression; ultrafine grinders operate principally by attrition 2021年5月5日 A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it Grinding Machine: Definition, Parts, Working 2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, Intro to Grinding Methods, Machines and Tools2021年10月14日 Maintenance method of large machine tool ball screw wear based on brush plating technology and precision grinding technology October 2021 DOI: 101117/12Maintenance method of large machine tool ball screw wear

.jpg)

(PDF) Studies of a Rotary–Centrifugal Grain Grinder Using a

2019年9月27日 A scientific and technical literature review on machines designed to grind fodder grain revealed that the existing designs of grinding machines—those based on destruction by impact, cutting, or 2024年4月19日 Discover the inner workings of grinding machines and learn how they transform raw materials into finished products 899 Sheridan Dr, West Chester, Pennsylvania Mon – Sat: 9:00am–18:00pm Sunday CLOSED Grinding Method: Grinding Wheel Material: Grinding Wheel Size: Grinding Speed: Grinding Pressure: Grinding Accuracy: Grinding Capacity The Grind: Understanding The Processes Of Grinding Machines2024年4月18日 Safety: Safety is a top priority in any industry, and CNC grinder machines offer several safety advantages over manual grinding methods These machines are equipped with advanced safety features, including interlocks and protective enclosures, which prevent access to hazardous areas during operation Additionally, CNC grinder machines minimize The Powerful Advantages Of A Cnc Grinder Machine ForHere’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas 1 Surface Grinders: A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table 2 Cylindrical Grinders: A cylindrical grinder is used for shaping the outside of a workpiece 3What Is Grinding Machine? Definition, and Types Mechdaily

Basics of the Cylindrical Grinder Purdue University

2024年10月10日 A cylindrical grinder operator must be familiar with the machine itself, as well as how to select and utilize wheels, workholding, and coolant, in order for the grinding operation to be successful This foundational knowledge is necessary to reduce scrap, increase quality and production rates, and lower costs