Mining Mill Plant In Wanaprthy

GOVERNMENT OF TELANGANA DEPARTMENT OF

2019年2月14日 Scope For Industrial Growth in Wanaparthy District Wanaparthy District has potential for many industries depending on the availability of resources as follows:3 天之前 When looking for a longterm and efficient way to mine, concentrate and deliver minerals, it is essential to understand each phase of the process in detail AFRY's mining expertise is built on a solid foundation of process Mineral processing plants AFRY2020年12月3日 An examination of the molybdenum, copper and iron grade changes over a 10day period for both mill on and off modes of closedcircuit mill showed that in the milloff mode, A process mineralogy approach to study the efficiency of 2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material

.jpg)

Mine land rehabilitation: Modern ecological approaches for

2018年1月20日 Abstract Despite the urgent demand for sustainable mining, the revegetation and rehabilitation of areas degraded by mining activities remain challenging Uncertainties 2019年3月1日 Crawford proposed a complete reconciliation flowscheme where each step of the operation is examined sequentially from model to mine, mine to mill, mill to smelter or refiner Proactive reconciliation as a tool for integrating mining and 2023年5月3日 Mineral processing plant is a plant in which mineral processing is implemented to obtain concentrate products that are suitable for metallurgy or other industrial applications It is Mineral Processing Plant SpringerLinkMinetoMill is an operating strategy for mining operations to enhance the performance of mining and downstream processing activities One of the key objectives of the MinetoMill strategy is to maximize operations profitability Physical Processing: Innovations in Mineral

.jpg)

Mining Mill Plant In Wanaprthy technesrl

Mining Mill Plant In Wanaprthy Grinding mills for mining and minerals processing Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry Whatever minerals you process, wherever your operation may be, Multotec will help ensure your mineral processing plant is optimised to deliver the lowest cost per ton From individualised equipment to complete plants – greenfield or Mineral Processing Plants Multotec2023年10月10日 This mine uses several SAG mills as part of its operations to produce over 1 million tonnes of copper annually In addition, there are other notable examples such as Grasberg Mine in Indonesia and Collahuasi Mine in Understanding the SAG Mill in Copper Ore 2024年1月8日 drilltomill plant optimization at altynalmas pustynnoye gold mine *S Esen 1 , M Daniel 1 , B Dzhalolov 2 , B Bachramov 2 , J Geronimo 2 , A Kalmatayev 2 1 Esen Mining Consulting Pty LtdDRILLTOMILL PLANT OPTIMIZATION AT ALTYNALMAS

Understanding AG Mills Basics and Their Role in Mining

Applications of AG Mills in Mining AG mills are widely used in mining operations around the world, as they are essential for reducing the size of ore and preparing it for further processing AG mills are commonly used in gold and copper mines, as well as other types of mines that require the grinding of ore2024年10月13日 Understanding the operation of grinding mills in the mining and mineral processing industry Grinding mills are crucial equipment in the mining and mineral processing industry, used primarily for the reduction of ore and mineral particles The proper functioning of grinding mills is vital for the efficiency of the overall processing plantUnderstanding the operation of grinding mills in the mining 2024年9月20日 5 >> UNDErsTaNDINg MINE TO MILL Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development and use for the last 20 years Implemented effectively, numerous operations have experienced productivity gains from Mine to Mill in the range of 1020%UNDErsTaNDINg MINE TO MILL 911 Metallurgist2022年8月14日 The composition and properties of commercial materials are extremely diverse, as are the technologies for their extraction and processing The design of mining and processing plants is a complex task, which is solved by multidisciplinary teams of engineers, geologists, architects, economists, marketers and other specialistsMining and processing plant engineering design ESFC

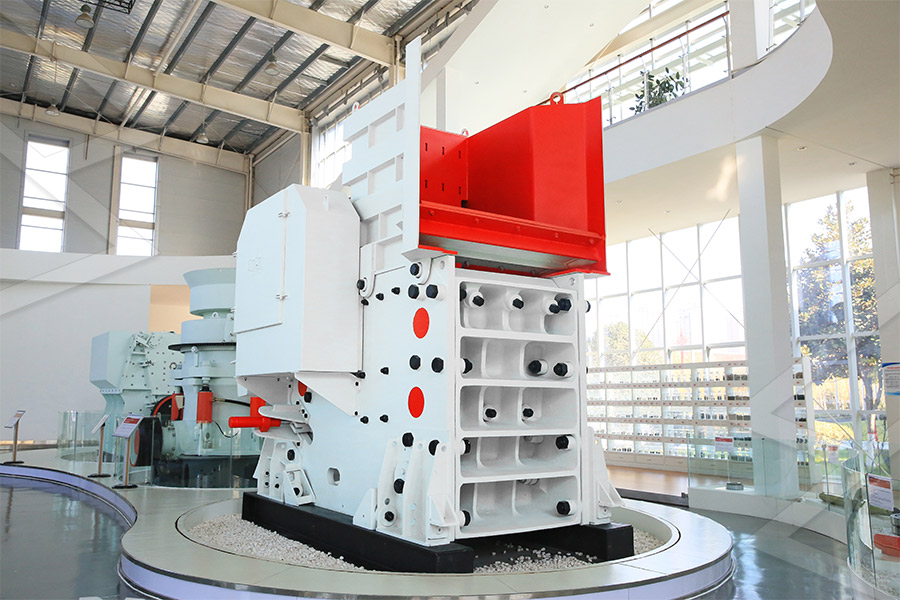

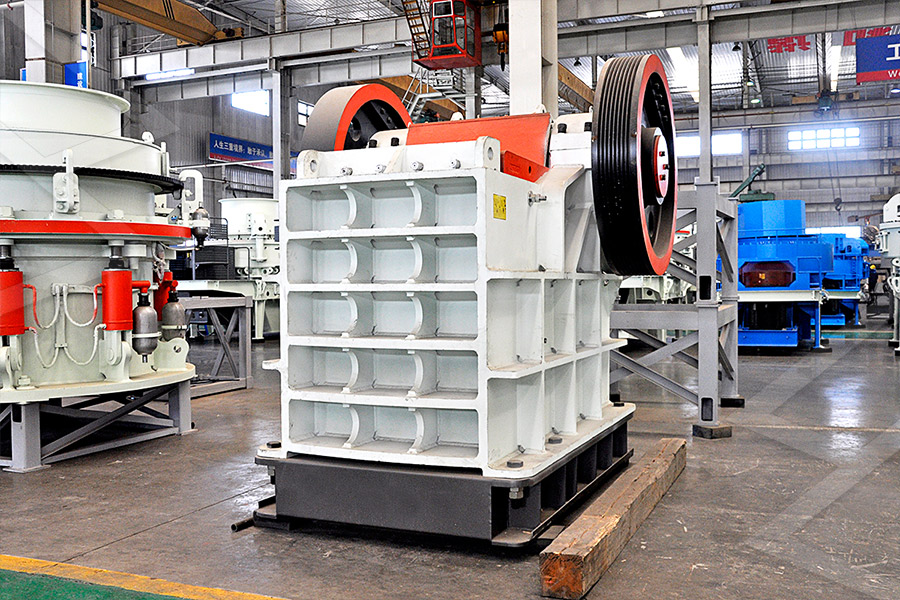

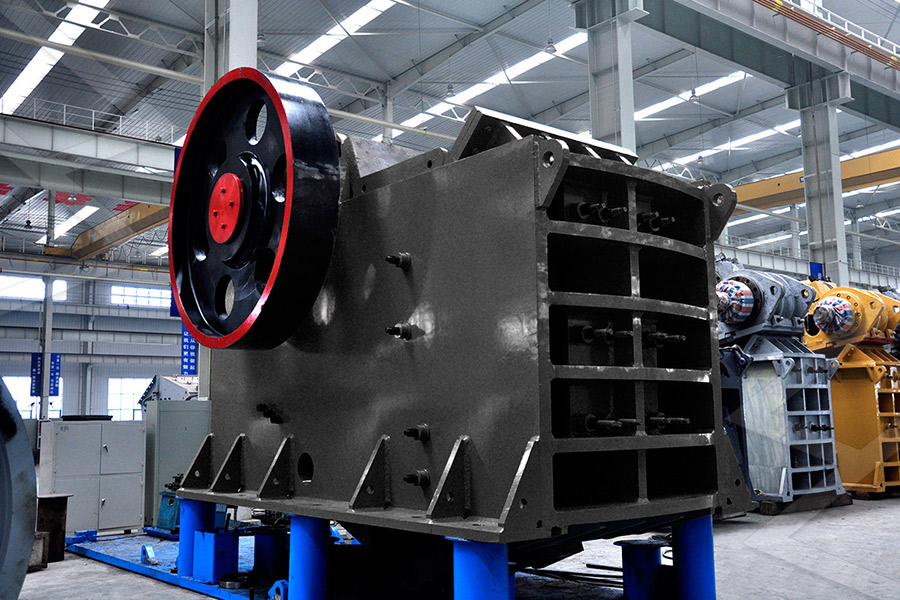

Mining Mill manufacturers suppliers MadeinChina

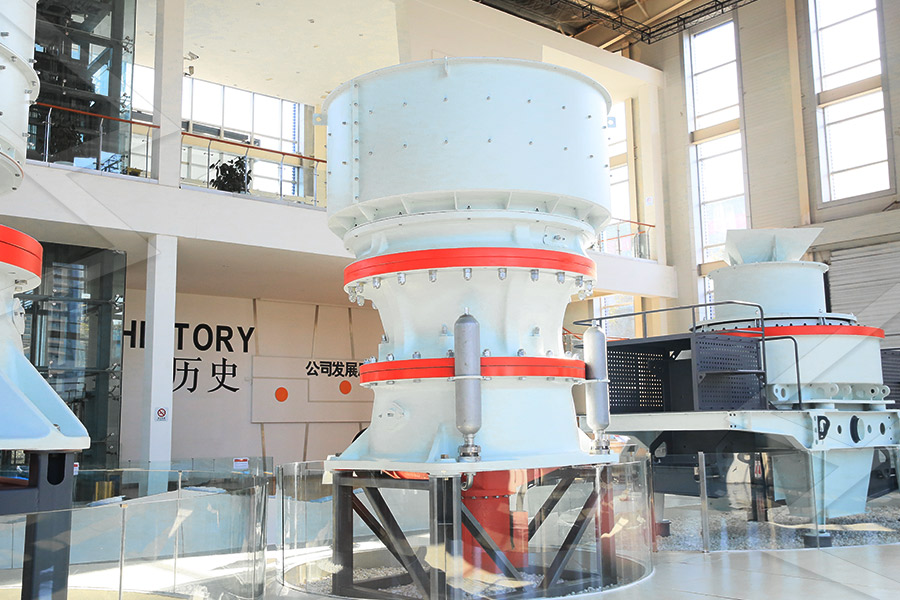

Mining Mill manufacturers suppliers, China Mining Mill manufacturers, suppliers factory directory, find Chinese Mining Mill manufacturers, suppliers, factories, exporters and wholesalers easily on MadeinChina Gold Recovery Equipment , Gold Elution Electrowinning Plant , Ball Mill : Mgmt Certification: ISO 9001, ISO 9000, ISO 2019年3月1日 Instead of using the common names found in the literature – F1, F2, F3, and so on –, which suggest that these numbers are to be used as ‘factors’, the proposed model defines five reconciliation ‘indicators’ instead, which are named as: Model Indicator (MI), Planning Indicator (PI), Operation Indicator (OI), Mine Reconciliation (MR) and Plant Reconciliation Proactive reconciliation as a tool for integrating mining and 2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 inGrinding Mills Common Types 911Metallurgist2024年4月26日 The ore is then extracted and transported to the processing plant b Underground Mining: Underground mining is employed when the iron ore deposit is located at significant depths It involves creating underground tunnels and shafts to access the ore Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) and semi Iron Ore Processing: From Extraction to Manufacturing Mining

.jpg)

sbm/sbm crusher plant in wanaprthymd at main

Contribute to chengxinjia/sbm development by creating an account on GitHub2024年4月11日 Location: Mount Zynai Industrial Park, Barangay Santa Cruz, Diplahan, Zamboanga Sibugay, Mindanao, Philippines; Coordinates (): 7, 122 (approximate); Background On June 18, 2022, land preparation for the proposed steel plant began at Mount Zynai Industrial Park in Diplahan town of Zamboanga SibugayMount Zynai Integratred Steel Mill and Smelting PlantHorizontal Mill Plant Units offer complete support in grinding circuit selection, as well as execution, service and operation Menu Close Mining Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process Horizontal Mill Plant Units MetsoThe definition of plant, what classified plant are and what classified plant need to be registered before use are discussed There are many types of plant at a mine site but there is a particular group, related to a higher operational hazard, referred to as 'classified plant', that has specific regulatory requirements What types of plant are found on mining operations?

Mining Grinding and Processing WEG

Constant speed Low speed synchronous motors Synchronous motors are widely used in mill driving systems at a constant speed using an air clutch between the motor shaft and mill p2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers3 天之前 When ore enters the plant from underground it first needs to be milled to reduce its size so that the gold is liberated from the host rock South Deep’s milling circuit consists of a singlestage semiautogenous grinding mill (SAG) and a pebble crusher for primary milling, followed by secondary milling using two overflow ball millsGold Fields South Deep Gold Mine How we process2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting efficient Stirred media mills in the mining industry: Material

.jpg)

Key Mining projects and plant upgrades in Zimbabwe

2023年6月6日 Caledonia Mine has also constructed a 12MW Solar Plant at Blanket, at a cost of approximately USD14 million RIOZIM Cam And Motor Mine (Expansion Project) Kadoma RioZim Cam and Motor Mine Biox Plant was officially commissioned by His Excellency, the President of the Republic of Zimbabwe, Cde Dr E D Mnangagwa on 14 April 20222021年11月22日 The substantial wastes generated are coal ash from the thermal power plants, mill tailings and smelter slag from the copper and zinc industry, red mud from the aluminium industry, etc Table 1 illustrates the major industrial solid wastes produced due to the mining and allied activities in IndiaUtilization of mill tailings, fly ash and slag as mine paste 2012年9月24日 The production of minerals for economic use is a twostage process, involving mining to extract the mineral from the ground, and processing to convert the mineral into a marketable productUSING PROCESS INTEGRATION 2015年8月24日 The Anglo American phosphate mine is located in the Brazilian state of Goi#225;s and possesses one of Brazil’s most important phosphate rock deposits, with the site being the country’s second largest producer of phosphate rock concentrate Despite the site having been in operation since 1979, the mining team only started using explosives in 2004 OneMine Fragmentation Optimisation – Adopting Mine to Mill

Minetomill optimisation Mining Magazine

2018年11月5日 Minetomill optimisation is a holistic approach to minimising energy and operating costs in mineral processing by optimising all stages within the size reduction process, explains Motion Metrics mine and plant operators must optimise the particle size distribution for each stage of comminution based on an understanding of how each stage 2002年3月11日 For mining and milling of uranium a distinction is made between conventional mining and in situ leach (ISL) mining A conventional mining operation consists of underground/or open pit operation and a process plant to extract the uranium from the host rock An ISL operation consists of well fields and a process plant to extract the uraniumgood practice in the management of uranium mining 2024年5月11日 Benefits of Mini Mill Plants for Farmers Increased Efficiency: Mini mill plants are specifically designed to cater to the needs of smallscale farmers, providing them with the ability to process their crops onsite quickly and efficiently By eliminating the need to transport crops to large milling facilities, farmers can save time and money while also increasing their productivityThe Rice Revolution: A Mini Mill Plant for SmallScale FarmersOur Plants in Action Get to know some of our featured projects that uniquely optimised the processing power of our customers’ plants Case Study: Multotec expertise cuts wear at Phosphate Plant A phosphate mine in Morocco is benefitting from Multotec’s scrubber liners expertise and extensive experienceMineral Processing Plants Multotec

Dealing With Scat in Mill Processing PumpEng Submersible

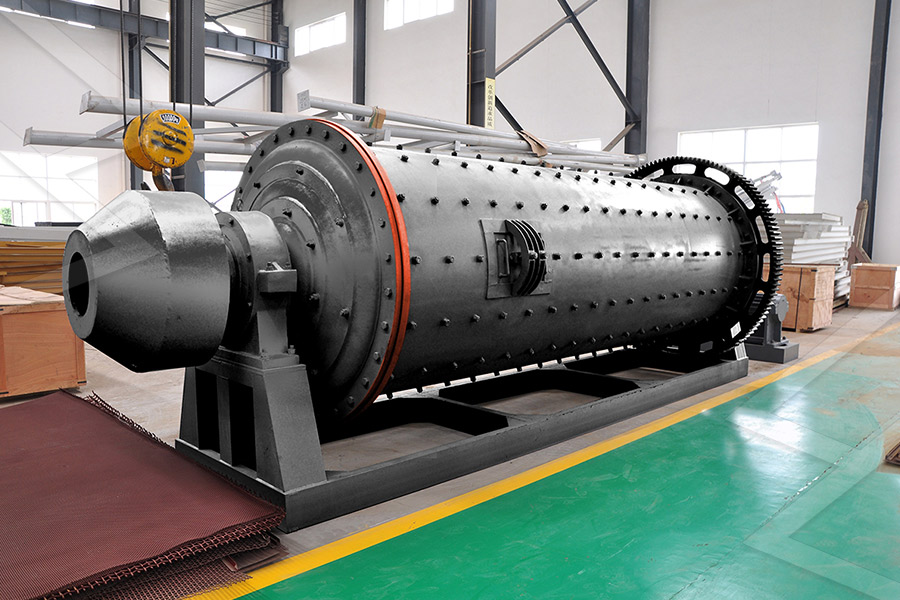

In a mining plant or processing mill, they have a big grinding circuit for crushing raw material, these are usually Ball or SAG mills Inside these Sag/Ball mill are big steel balls that grind ore via an impact process In simple terms, these hard metal steel balls get to the top of the rotating chamber and fall down crushing the ore being 2023年8月29日 %PDF15 %âãÏÓ 119 0 obj > endobj xref 119 30 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n Modular Plants: Gold Processing2 天之前 The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale ore beneficiation plant Dry grinding: suitable for materials that react with water, such as building stones such as cement and marble Due to Ball Mill Mining Grinding Mill JXSC Machinery2023年10月10日 This mine uses several SAG mills as part of its operations to produce over 1 million tonnes of copper annually In addition, there are other notable examples such as Grasberg Mine in Indonesia and Collahuasi Mine in Understanding the SAG Mill in Copper Ore

.jpg)

DRILLTOMILL PLANT OPTIMIZATION AT ALTYNALMAS

2024年1月8日 drilltomill plant optimization at altynalmas pustynnoye gold mine *S Esen 1 , M Daniel 1 , B Dzhalolov 2 , B Bachramov 2 , J Geronimo 2 , A Kalmatayev 2 1 Esen Mining Consulting Pty LtdApplications of AG Mills in Mining AG mills are widely used in mining operations around the world, as they are essential for reducing the size of ore and preparing it for further processing AG mills are commonly used in gold and copper mines, as well as other types of mines that require the grinding of oreUnderstanding AG Mills Basics and Their Role in Mining 2024年10月13日 Understanding the operation of grinding mills in the mining and mineral processing industry Grinding mills are crucial equipment in the mining and mineral processing industry, used primarily for the reduction of ore and mineral particles The proper functioning of grinding mills is vital for the efficiency of the overall processing plantUnderstanding the operation of grinding mills in the mining 2024年9月20日 5 >> UNDErsTaNDINg MINE TO MILL Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development and use for the last 20 years Implemented effectively, numerous operations have experienced productivity gains from Mine to Mill in the range of 1020%UNDErsTaNDINg MINE TO MILL 911 Metallurgist

Mining and processing plant engineering design ESFC

2022年8月14日 The composition and properties of commercial materials are extremely diverse, as are the technologies for their extraction and processing The design of mining and processing plants is a complex task, which is solved by multidisciplinary teams of engineers, geologists, architects, economists, marketers and other specialistsMining Mill manufacturers suppliers, China Mining Mill manufacturers, suppliers factory directory, find Chinese Mining Mill manufacturers, suppliers, factories, exporters and wholesalers easily on MadeinChina Gold Recovery Equipment , Gold Elution Electrowinning Plant , Ball Mill : Mgmt Certification: ISO 9001, ISO 9000, ISO Mining Mill manufacturers suppliers MadeinChina2019年3月1日 Instead of using the common names found in the literature – F1, F2, F3, and so on –, which suggest that these numbers are to be used as ‘factors’, the proposed model defines five reconciliation ‘indicators’ instead, which are named as: Model Indicator (MI), Planning Indicator (PI), Operation Indicator (OI), Mine Reconciliation (MR) and Plant Reconciliation Proactive reconciliation as a tool for integrating mining and 2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 inGrinding Mills Common Types 911Metallurgist